Eftirfarandi upplýsingar eru fengnar á heimasíðu FIA og það er klárt mál að 4ra púnkta veltibogi er ekki lengur löglegur fyrir bíla sem fara fljótar en 11.49

Tekið úr þessum tenglum:

http://argent.fia.com/web/fia-public.nsf/50E84CFBB895D4EFC125767E004C39C0/$FILE/2010%20Drag-RT%20et%20Proc%20Course_27.10.09.pdf.pdf

http://argent.fia.com/web/fia-public.nsf/3B508127A498C9ABC12573A90051BFA3/$FILE/2009-DessinsDrag%20_10.11.08.pdf

4.5 ROLL BAR

Roll bar mandatory in all cars (including T-tops) running 11.00 (*7.00) to 11,49 (*7,35), in convertibles running 11.00 (*7.00) to 13,49 (*8,25), and in dune-buggy type vehicles running 12.00 (*7.50) seconds and slower. Permitted in all cars. See General Regulations 4.10, 10.6.

4.6 ROLL CAGE

Roll cage mandatory in cars running 10.99 (*6.99) or quicker or any car exceeding 135 mph (217.2 km/h).

Full bodied cars, with unaltered firewall, floor and body (from firewall rearward, wheeltubs permitted), running between 10.00 (*6.40) and 10.99 (*6.99) roll bar permitted in place of roll cage. In convertibles running 10.99 or quicker or exceeding 135 mph (217.2 km/h), roll cage mandatory. Cars running between 7.50 (*4.50) and 9.99 (*6.39) must have chassis inspected every three-years by the ASN and have a serialised sticker affixed to cage before participation.

All new Street Roadsters must conform to SFI Spec 10.4. Existing Street Roadsters must meet SFI Spec 10.4 at their next scheduled recertification.

Rear-engine dragsters must conform to SFI Spec 2.7B; vehicles running 8.49 to 7.50 and/or exceeding 180 mph (286 km/h) must meet appropriate SFI Spec for body used. Plating of chassis prohibited for all cars manufactured after 1/1/2004. All others must conform to specs for body style used, as listed in General Regulations 4.11, 10.6.

4.10 ROLL BARS

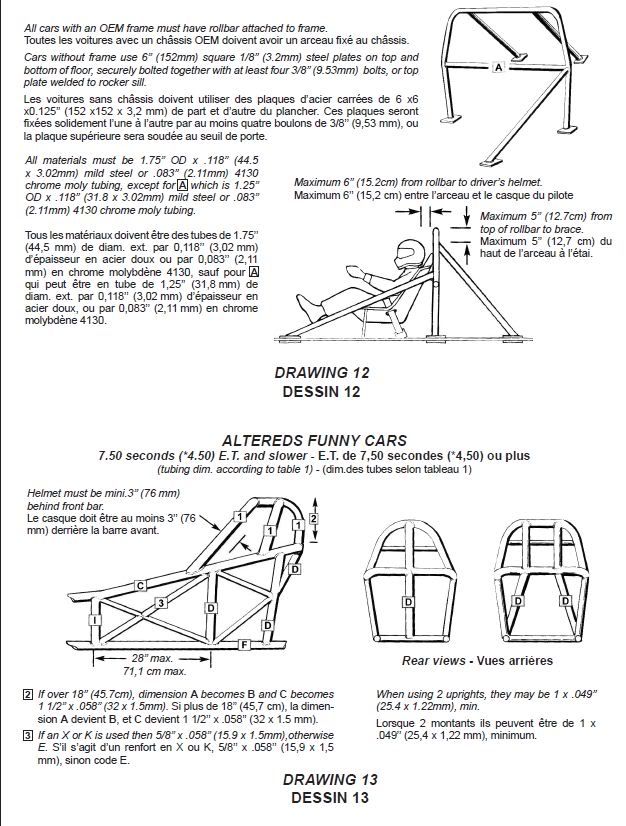

All roll bars must be within 6-inches (15.2 cm) of the rear, or side, of the driver’s head, extend

- in height at least 3-inches (7.6 cm) above the driver’s helmet with driver in normal driving position, and be at least as wide as the driver’s shoulders or within 1-inch (2.5 cm) of the driver’s door.

Roll bar must be adequately supported or cross-braced to prevent forward or lateral collapse of roll bar. Rear braces must be of the same diameter and wall thickness as the roll bar and intersect with the roll bar at a point not more than 5-inches (12.7 cm) from the top of the roll bar. Crossbar and rear braces must be welded to main hoop.

Sidebar must be included on driver’s side. The side bar must pass the driver at a point midway between the shoulder and elbow. Swingout-sidebar permitted. All roll bars must have in their construction a cross bar for seat bracing and as the shoulder harness attachment point; cross bar must be installed no more than 4 inches below, and not above, the driver’s shoulders or to side bar. All vehicles with OEM frame must have roll bar attached to frame; installation of frame connectors on unibody cars does not constitute a frame and therefore it is not necessary to have the roll bar attached to the frame. Unibody cars with stock floor and firewall (wheel tubs permitted) may attach roll bar with 6-inch (15.2 cm) x 6-inch (15.2 cm) x .125-inch (3.2 mm) steel plates on top and bottom of floor bolted together with at least four 3/8-inch (9.53 mm) bolts and nuts, or weld main hoop to rocker sill area with .125-inch (3.2 mm) reinforcing plates. All 4130 chrome moly welding must be done by approved TIG Heliarc process; mild steel (or ST51) welding must be approved MIG wire feed or approved TIG heliarc process. Welding must be free of slag and porosity. Any grinding of welds prohibited. See illustration (Drawing 12).

Roll bar must be padded anywhere driver’s helmet may contact it while in driving position. Adequate padding must have minimum 1/4-inch (6.35 mm) compression or meet SFI Spec 45.1.

All cars running 180-mph or faster, SFI Spec 45.1 mandatory.

4.11 ROLL CAGE

All cage structures must be designed in an attempt to protect the driver from any angle, 360-degrees. All 4130 chrome-moly tube welding must be done by approved TIG heliarc process; mild steel tube welding must be approved MIG wire feed or TIG heliarc process. Welding must be free of slag and porosity. any grinding of welds prohibited. Plating of chassis prohibited for all cars manufactured after 1/1/2003; unless otherwise noted in Class Requirements; painting permitted. Additionally, roll cage must be padded any where the driver’s helmet may contact it while in the driving position. Pro Modified, TMD, TMFC, Pro Stock, Funny Car & Top Fuel, and any car running 180 mph (305 km/h) or faster, padding must meet SFI Spec 45.1. See illustrations.

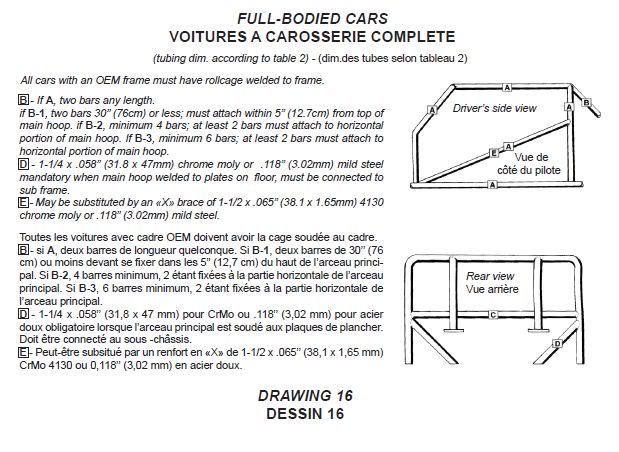

Open Bodied cars (see illustrations)

When driver is in driving position in an open bodied car, roll cage must be at least 3-inches (76 mm) in front of helmet. Cars without crossmember above driver’s legs must have a strap or device to prevent legs from protruding outside chassis. On front-engine dragster, seat uprights and back braces must be arranged such that a flat surface passed over any two adjacent members will not contact the driver seat or containment. Additional uprights, max 30-degrees from vertical, must be added until this criteria is satisfied. When non-vertical upright or «running W» side bay designs are used (i.e., uprights installed at greater than 30-degrees from vertical), adjacent roll cage diagonals mustbe the same size as that required for the upright. Motor mount and/or rear end uprights (except rear engine dragster) may be rectangular tubing, 1 3/4-inch x 1-inch x .058-inch (44.5 x 25.4 x 1.5 mm) CM or MS minimum. For all vehicles required to meet SFI Specification 2.3N, 2.1, 2.2B, 2.4B, 2.5B, 2.6, 2.7B, 10.1E, 10.4 and 10.5 the upper roll-cage members must have head/helmet guards of one-inch (25.4 mm) by .058-inch (1.5 mm) round tube on all new chassis or at scheduled recertification. All new Street Roadsters must conform to SFI Spec 10.4. Existing Street Roadsters must meet SFI Spec 10.4 at their next scheduled recertification.

Full Bodied Cars (see illustration)

On full bodied car, with driver in driving position, helmet must be in front of main hoop. If helmet is behind or under main hoop, additional tubing same size and thickness as roll cage must be added to protect driver. Main hoop may be laid back or forward but driver must be encapsulated within the required roll cage components. On unibody cars with stock floor and firewall (wheel tubs permitted), the roll cage may be bolted or welded to the floor/rocker box via 6-inch x 6-inch x .125-inch (152 x 152 x 3.2 mm) steel plates similar to the roll-bar attachment requirements of paragraph 4.10. Unless attaching to OEM floor or frame, the minimum requirements for a frame member to which a roll-cage member is attached are 1 5/8-inch (41.2 mm) x .118-inch (3.0 mm) MS or .083-inch (2.1 mm) CM round and/or 2-inch x 2-inch x .058 (50.8 x 50.8 x 1.5 mm) MS or CM rectangular.

All cage structures must have in their construction cross bar for seat bracing and as the shoulder harness attachment point; cross bar must be installed no more than 4-inches (102 mm) below, and not above, the driver’s shoulders or to side bar. All required rear braces must be installed at a minimum angle of 30-degrees from vertical, and must be welded in. Side bar must pass the driver at a point midway between the shoulder and elbow.

Unless an O.E.M. frame rail is located below and outside of driver’s legs (i.e. ‘55 Chevy, ‘65 Corvette, etc.) a rocker or sill bar, minimum 1 5/8-inch (41.2 mm) x .083 (2.1 mm) CM or .118 (3.0 mm) MS or 2-inch x 2-inch x .058-inch (50.8 x 50.8 x 1.5 mm) CM or MS rectangular, is mandatory in any car with a modified floor or rocker box within the roll cage uprights (excluding six square feet of transmission maintenance opening). Rocker bar must be installed below and outside of driver’s legs, and must tie into the main hoop, the forward hoop, frame, frame extension or side diagonal. Rocker bar may not tie into swing out side bar support. If rocker bar ties into side diagonal more than 5-inches (127 mm) (edge to edge) from forward roll cage support or main hoop, a 1 5/8-inch (41.2 mm) x .083 (2.1 mm) CM or .118 (3.0 mm) MS brace/gusset is mandatory between the diagonal and forward roll cage support or main hoop.

Swing out side bar permitted on O.E.M. full bodied car 8.50 E.T. and slower. The following requirements (a through d) are enforced on all cars:

a. 1 5/8-inch (41.2 mm) O.D. x .083-inch (2.1 mm) (CM) or .118-inch (3.0 mm) (MS) minimum. Bolts / pins must be 3/8-inch (9.5 mm) diameter steel, minimum and in double shear at both ends.

Male or female clevis(es) permitted. Male clevis must use two minimum 1/8-inch (3.2 mm) thick brackets (CM or MS) welded to each roll cage upright; female must use minimum 1/4-inch (5.4 mm) thick bracket (CM or MS) welded to each roll cage upright. Pins must be within 8-inches (204 mm) of the vertical portion of both the forward and main hoops. A half cup backing device must be welded to the vertical portion of the main hoop (inward side) or the upper end of the swing out bar (outward side), minimum .118-inch (3.0 mm) wall (CM or MS) extending at least 1 5/8-inch (41.2 mm) past the center of the pins. A clevis assembly utilizing a minimum .350-inch (8.90 mm) thick male component and two minimum .175-inch (4.45 mm) thick female components may use a 1/2-inch (12.7 mm) diameter grade 5 bolt, and does not require a half cup backing device.

c. Sliding sleeves of 1 3/8-inch (35 mm) x .083-inch (2.1 mm) CM or .118 (3.0 mm) MS, with minimum 2-inch (51 mm) engagement, are permitted in lieu of the upper pin/cup.

d. All bolt/pin holes in the swing out bar must have at least one hole diameter of material around the outside of the hole.

For chassis certification, and on all cars requiring a roll cage:

On all cars requiring a roll cage, if the O.E.M. firewall has been modified (in excess of 1 square foot (929 cm2) for transmission removal, not including bolted in components) a lower windshield or dash bar of 1 1/4 x .058-inch (32 x 1 mm) 4130 chrome moly or 1 1/4 x .118-inch (32 x 3.0 mm) mild steel is mandatory connecting the forward cage supports